For more than four decades, Wills Wing has manufactured world-class hang gliders for flying enthusiasts of all abilities. Since its founding in 1973, the Southern California-based company has grown to become the largest manufacturer of hang gliders in the world, offering the most comprehensive lineup of hang gliders available anywhere. From basic gliders for beginner and casual recreational fliers to advanced models for the most seasoned and competitive pilots, the hang glider manufacturer develops products to fi tall flying styles and experience levels.

Throughout its history, Wills Wing has focused on leveraging design and manufacturing technologies to boost efficiency and maximize the impact of its small, tightly knit team, as well as to maintain high levels of quality, safety, and performance. “We’ve witnessed incredible technological advances both in hang gliding and in the tools that we utilize to design and manufacture our products,” explains President, Managing Partner, and Lead Designer Steve Pearson, one of a team of test pilots who test-fly every hang glider that the company makes before delivery to customers. “Over the years, our hang gliders have set the distance record many times, including the first 300-mile flight in 1990 and the current record of 475 miles in 2013, a flight that lasted 11 hours

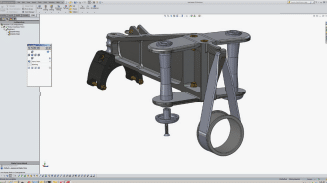

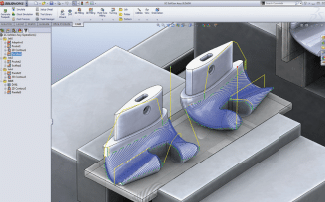

After evaluating 3D modelling packages, Wills Wing chose SOLIDWORKS® design software because it is easy to use, provides advanced design visualization capabilities, and supports the CNC machining centre that Wills Wing acquired to support growth. “The power of SOLIDWORKS is the extraordinary range of design tools packaged within an easy-to-use interface,” Pearson stresses. “Since our selection of SOLIDWORKS in 1996, the software has grown in capabilities and intuitiveness to the point that it would be impossible to do what we do without it.”

Wills Wing is able to develop technically sophisticated products with limited resources because of the design visualization capabilities provided by SOLIDWORKS software and AMD FirePro professional graphics. For example, Pearson takes advantage of order-independent transparency to obtain pixel accurate representations of a model and surrounding geometry, and AMD Eyefinity® technology to view models across multiple displays, maximizing design visualization.

With SOLIDWORKS software and AMD FirePro professional graphics, Wills Wing has virtually eliminated the need to create photorealistic design renderings as a separate step because of the high graphical quality of RealView in SOLIDWORKS, which incorporates ambient occlusion, scene refl ections, advanced shading, translucency, and self-shadowing. “I can effectively design with RealView turned on without any performance loss, even with assemblies of 1,000 parts.