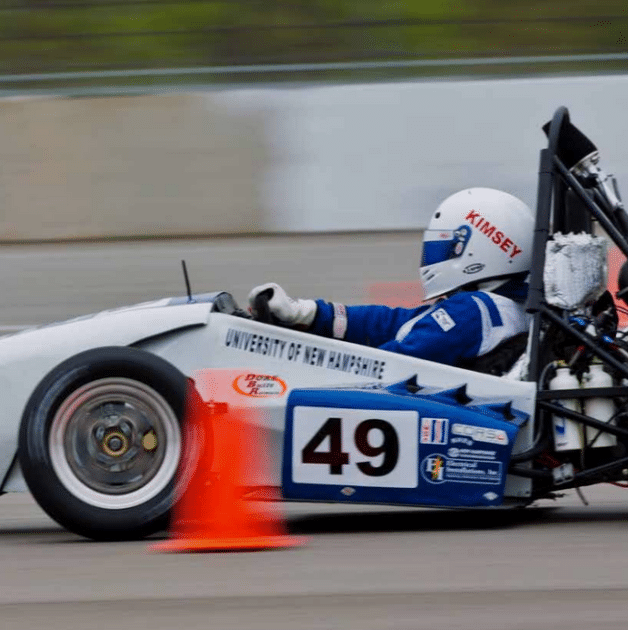

Empowering UNH Precision Racing with SOLIDWORKS Education Edition -

The University of New Hampshire Society of Automotive Engineers (SAE) Formula One Racing Team, known as UNH Precision Racing, transformed its approach to motorsports engineering by adopting SOLIDWORKS Education Edition. As part of the College of Engineering and Physical Sciences, UNH provides hands‑on automotive engineering experiences that prepare students for careers in advanced manufacturing and competitive design. Switching to SOLIDWORKS allowed team members to master industry‑standard 3D CAD tools while focusing on performance rather than software complexity.

Streamlined 3D CAD Modeling and Collaboration -

Prior to 2009, UNH Precision Racing relied on a less intuitive CAD system that hindered interdisciplinary teamwork. SOLIDWORKS Education Edition delivers an integrated design environment where frame, suspension, electronics, controls, and aerodynamics subteams can collaborate seamlessly. With photorealistic rendering and design visualization, students communicate their concepts clearly to SAE judges and sponsors, reducing misunderstandings and accelerating decision‑making.

Advanced Simulation for Performance Optimization -

Finite element analysis (FEA), flow simulation, and frequency studies built into SOLIDWORKS enable UNH’s engineers to validate and refine critical components before fabrication. By running structural analyses on lower control arms, flow analyses for aerodynamic efficiency, and resonance tests on intake systems, the team minimizes weight and maximizes safety. Early detection of potential failures through collision detection and stress mapping cuts prototyping cycles and machining costs.

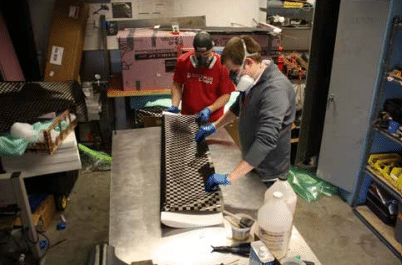

Efficient Prototyping and CNC Integration -

Once the design is optimized, SOLIDWORKS’ compatibility with Mastercam® streamlines the transition from virtual model to machined part. Captains like Drummond Biles report that the ease of generating CNC code directly from SOLIDWORKS assemblies reduces shop time and material waste. This rapid prototyping workflow not only improves part quality but also gives students real‑world experience in automotive manufacturing processes.

Historic Performance Gains and Student Engagement -

Since adopting SOLIDWORKS Education Edition, UNH Precision Racing achieved its best season in 2013–2014, ranking 26th overall against well‑funded competitors. The accessible CAD environment has attracted more students to the SAE team, fostering a culture of continuous improvement and peer learning. By equipping future mechanical engineers with SOLIDWORKS CAD, simulation, and data management skills, UNH is driving innovation in collegiate motorsports and preparing graduates for successful careers in the automotive and aerospace industries.