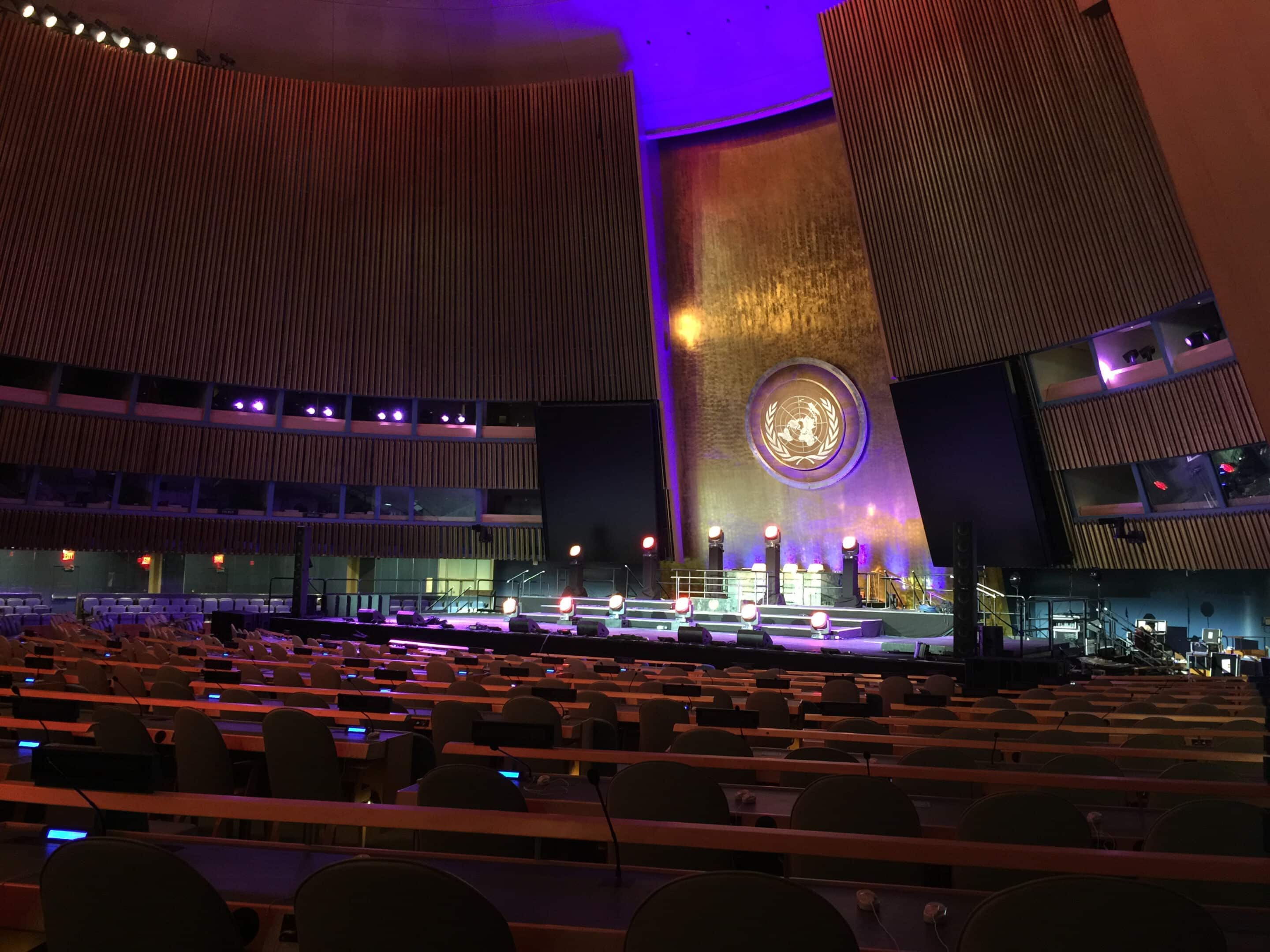

Since its founding in 1990, K-array has built a reputation as a pioneer in professional audio, marrying deep acoustical expertise with sleek, award-winning aesthetics. Based in Florence, Italy, the company’s signature slim-array speakers overcome the bulk and weight of traditional wooden transducer systems, delivering exceptional sonic accuracy for touring, live events, installed sound, and broadcast applications. By leveraging sheet-metal fabrication and line-array technology, K-array offers solutions that range from large-arena setups to nearly invisible theatre, worship, and corporate systems, all designed for maximum performance and efficiency

Recognising the need for seamless exchange and faster iteration, engineering manager Nicola Pieri led the switch to SOLIDWORKS Standard 3D design software. “All of our partners and vendors use SOLIDWORKS software, and it became increasingly necessary to communicate with them more efficiently and effectively,” he explains. The company later augmented its toolkit with SOLIDWORKS Simulation Premium for analysis and SOLIDWORKS Composer for documentation, laying the foundation for a fully integrated development ecosystem

The move paid off immediately: design cycles and time-to-market both fell by 20 percent, while a shared SOLIDWORKS environment boosted design reuse by 30 percent. Projects now begin with R&D engineers creating detailed 3D models and drawings that are seamlessly transmitted to fabricators. Once manufactured, the Production Team assembles and rigorously tests each unit before shipment. This streamlined process—powered by SOLIDWORKS’s intuitive interface—has cut the design-and-drawing phase in half, enabling K-array to deliver cutting-edge products more rapidly to customers around the globe

Incorporating SOLIDWORKS Simulation Premium allowed K-array engineers to perform stress and deflection analyses during early design stages, identifying potential performance or safety issues before any metal is cut. Using structural analysis, they calculate the precise thickness and geometry needed to meet lifting-equipment safety standards—minimising prototypes and costly rework. Meanwhile, SOLIDWORKS’s advanced sheet metal features have reduced scrap by 20 percent by optimising nesting and material usage. “During production startup, we continuously interact with suppliers to best assess fabrication feasibility,” Pieri notes, underscoring the twin benefits of cost savings and stronger supply-chain collaboration.

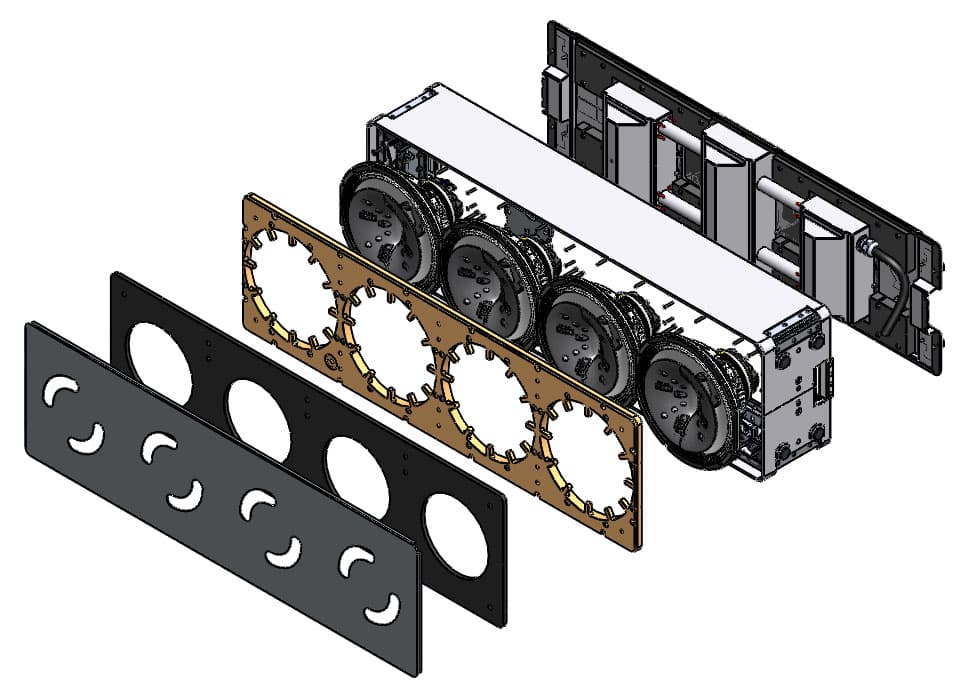

Beyond design and analysis, K-array adopted SOLIDWORKS Composer to replace its legacy Adobe-based workflow for user manuals and service guides. Composer taps directly into SOLIDWORKS models to generate high-quality graphics, exploded views, and step-by-step illustrations—with no intermediary file conversions. This end-to-end integration accelerates preparation of technical documentation, ensuring accuracy and consistency between the product and its supporting materials. As a result, K-array can deliver both hardware and documentation in lockstep, further strengthening its reputation for innovation and reliability.

Enjoy 30% off for 30 days!

To celebrate SOLIDWORKS turning 30 we are offering 30% off of all SOLIDWORKS packages* until the 20th of June

To take advantage of this get in touch below!